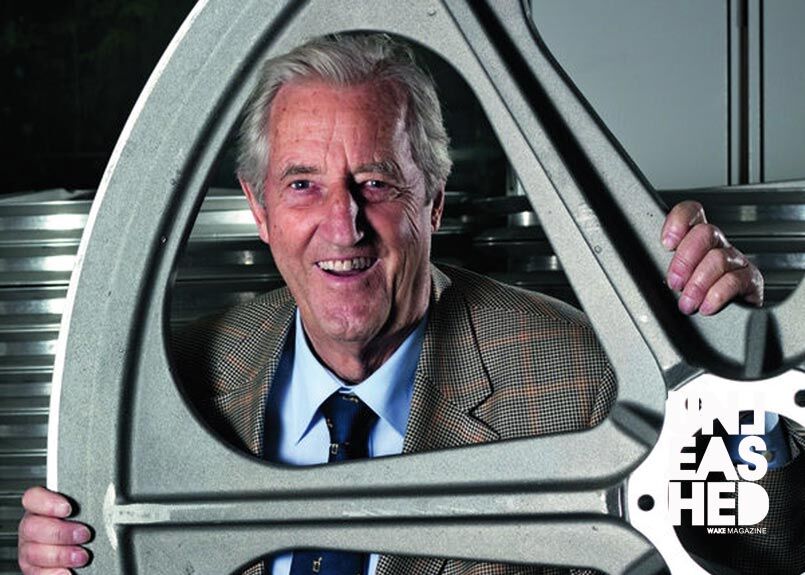

01 Dec Bruno Rixen | 1931-2020

Bruno Rixen , One idea , one goal , one life !

BRUNO RIXEN , the lost of the WATER CABLESKI Inventor …

We’re all thanks full about what Bruno Rixen was accomplish during this whole life dedicate to waterskiing and wakeboarding . How can this man get this insane idea to use Cableways to improve this watersports all round the world , and give access to the sport to the less rich people, democratize this discipline , and make those parks a real leisure waterparks…

The history of cablepark with Bruno Rixen

One Men One History !

When Bruno Rixen look back, there are many positive circumstances that contributed to his success, such as growing up in the country and in a family business environment that included a guest house, a colonial produce business and a small farm.When his father died in 1944, I had to take on responsi- bility at an early age and help my mother with the many additional tasks that needed to be taken care of.

Bruno Rixen Interview for the 2014 GUIDE OF CABLEPARKS

My transition to professional life occurred as soon as I left secondary school (ìMittlere Reifeî). I managed to nd an apprenticeship as a vehicle mechanic in a small repair workshop with two master mechanics and two apprentices. I mainly worked on tractors and diesel engines, which gave me an extremely challenging education. I took the apprenticeship certi cation exam ahead of time, and passed it with distinction. I gave advice to the farmers in my home village of Gro Buchwald and the local area during the change from working with horses to the use of tractors, for which I was occasionally paid commission.

Find all wake spots in the world on

Apprenticeship

In the second year of my apprenticeship I established a company for threshing ax for the farmers, for which I purchased a machine and modi edit until it was functional. I nanced my studies in Kiel from selling tractors and threshing ax, and was even able to afford a brand new BMW «Isetta». Following my studies, I invited a fellow student to go on a trip around Europe in the Isetta, and saw some young people water-skiing behind a boat in Holland. This was where I made a long-cherished wish come true. My tran- sition to 2 skis was seamless, and I was so impressed by the experience that I paid for my friend to have a go and even had to persuade him.

As an engineer at the Olympia typewriter factory (one of 13,000 employees), I then spent a great deal of time considering how I could continue to water-ski without the expensive motor boat. A cableway was an obvious choice as the pulling mechanism. I then started to draw and calculate. The fact that I had never seen a cableway before was an advantage. I therefore had no preconceptions in my technical decisions, but also had no idea of the many technical dif culties that I would encounter. Otherwise it would have been more sensible to give up. However, I had read the book by Oskar Schellbach entitled «Mein Erfolgs- Systemî – My Taste of Success, recognised the power of positive thinking and learned that you can only achieve your goals if you believe it is possible.

Working holidays

Manufacturing a pair of skis had already unexpectedly taken up several days of my holiday.

First I needed a 600 m long running cable with a diameter of at least 4 mm. A friend bought one for me. I obtained the detection pulleys from a combine harvester belonging to my brother. I was allowed to use trees to suspend the cable at a height of 6 m, for which the forest ranger charged 3 DM.

To begin with, a borrowed Lanz Bulldog tractor was used as the drive. I used a small trolley to travel down the 3 m long start ramp. The start worked immediately, and I travelled across Bordesholm Lake. Hurray, it had worked! At the 38∞ bend I suddenly had slack cable, and the acceleration that immediately occurred threw me into the reeds. My rst thought was: I’ll never manage to do a full lap! But where there’s a will, there’s a way. In my drawings I had discovered that the problem of changing direction could be solved if the skier veered to the right several metres before reaching the bend.

Serious problem

I soon discovered another much more serious problem. The running cable wraps around itself. If the skier did not keep his towing rope taut, it wound around the running cable. The connecting hook between the tow rope and the running cable levered it over the sharp edge of the next de ection pulley, it was nipped off and everything fell into the water.

I dread to think about the number of hours I spent splicing the two pieces of cable together!

In my second year, my voluntary helpers (and myself, of course) did not want to have to stop after every lap, but wanted to travel round continuously. In order to do this, the running cable had to be driven above water using another cable that led from the 2-groove cable wheel to the drive on the hill. The narrow 176∞ angle of this freely suspended double cable wheel was not a problem for us. Since the Bulldog was not always available, I attached my Isetta with the ax thresher and used it as a drive.

Managing the speed

In order to multiply the capacity, additional runners had to be coupled and uncoupled at full cable speed. This was the biggest challenge yet, and was at the back of my mind whatever I was doing. Finally I came up with an idea that was too good to be true: not starting beneath the cable like all the other cableways, but from the side on an 18 m long tow rope. The first drawings and theoretical calculations of the acceleration produced fantastic results. The practical proof was provided by a model of the cableway on land. It also confirmed that the invention of the 2-cable system for compensating for cable twisting was the only way to go.

However, the decisive test could only be carried out on the water.

Decisive test

Bredenbek Lake in Ahrensburg near Hamburg was a suitable lake, but unfortunately it was part of a landscape conservation area. However, this year there was no other alternative. I constructed my cableway with the help of my master mechanic and Ahrensburg assistants in order to operate it of cially for money, since we also had to check the demand for the cableway and whether it could be operated pro tably. However, it was no longer possible to obtain permission and carry out the construction work this summer.

By way of compensation, the company owner provided funds of 30,000 DM for my own cableway in Niendorf on the Baltic Sea coast, where we had obtained permission for a 1200 m long square cableway. The two running cables were 7 mm thick, therefore three times thicker than in Bredenbek, and all of the cable pulleys now had a diameter of 700 mm. The rectangular cableway was constructed using the minimum materials imaginable. The 3 de ection pulleys had a diameter of just 35 mm. The motor mast did not have a cantilever. It was therefore erected with a gradient of just 45∞. The diesel motor at the tip of the mast powered the two drive wheels, which now had a diameter of 70 cm.

Cableways launched

The Niendorf cableway represented the end of the prototype period.

Although the main development of the water ski cableway was now complete, improvements are always being made on the basis of new experience. One example of this is the automatic tow rope system, in which a catch fork collects the ball cable. The small transport cableway transports it downwards to the operating stand, where the handle remains in the magazine and the ball cable is then deposited in the upper magazine. A total of 12 tow ropes can be kept here ready for starting, as is still the case.

Each tow rope was brought back to the starting position individually using a small transport cableway. 4 carriers, each with 4 wedge clamps, were distributed around the 600 m long running cable. Each wedge clamp connected 2 cable ends together and ensured that the carriers would not slip. We were able to uncouple the tow ropes on the move, but were still unable to catch them. They fell into the water every time, and had to be brought back to the starting position by row boats. I erected the rst cableway with automatic tow ropes and silent encapsulated diesel motor with my Spanish partner Humberto Armas in Benidorm on the Mediterranean in 1965. To date, 14 million kilometres have been travelled by water ski during the 68,000 hours of operation of this cableway. We managed to keep this temporary operation going in June and July, until a demolition order arrived because the cableway was not permitted inside the landscape conservation area.

High potential

Another major problem therefore had to be solved. As I drove home one evening, I passed an old person’s home next to the lake, where I saw 20 chairs in 2 rows. I realised immediately that the old people had been watching us water skiing. I took a photograph and sent it to the head of the district authority with an explanation of the situation and the sporting value of water skiing.

On the basis of this, we were granted retrospective permission with the condition that that we dismantled the cableway every winter. A few years later, I developed a pneumatic control unit for the automatic tow rope system. In order to make operation even easier, the cableways are now controlled using a frequency converter, which ensures that a speed of 0.5 km/h is adhered to exactly during championships.

Find all wake spots in the world on

Important development

The next stumbling block followed soon afterwards. The two running cables stretched by differing amounts. This had to be compensated for every month to prevent cable damage, but with the 16 wedge clamps of the 4 carriers this was too time-consuming in the long run. After the 2 years in Bordesholm and the 2 years in Bredenbek it was clear that water-skiing with the cableway and also starting at full speed were possible, which had been disbelieved for quite some time, particularly by the T‹V (Technical Inspection Association). In the meantime, it had been established that suficient demand was available. This put us in a position to agree to a licence contract with a Swiss cableway manufacturer to the tune of 55,000 DM. This company was well known for its special designs, and had a large construction of ce with 60 engineers and technicians. The 1st cableway «Made in Switzerland» was to be erected at Lake Neuenburg.

Another important development is our 2-mast cableway, which only requires 10 % of the water surface and the cost. Ideally it should be 150 m long, it only has to be 20 m wide, and is not just suitable for beginners but can also be used by experienced water skiers and wakeboarders.

We often hire out these small cableways for short of cial events such as the Hamburg Alstervergn ̧gen (Hamburg Alster Enjoyment), the Kieler Woche (Kiel Week) and the Bregenz City Festival. We are the global market leader, and were presented with the Bavarian Export Award in 2010.

Spots around the world

Our 294 cableways can be found in 45 different countries all over the world. They have travelled 1.3 billion water ski kilometres during 4,224 years of operation without a single accident caused by technical problems.

The International Waterski & Wakeboard Federation IWWF is attempting to have wakeboarding recognised as an Olympic discipline for the year 2020. The high capacity of the cableway and the rapid spread of the sport because of the 2-mast cableway are playing a decisive role in this.

To read the FIRST GUIDE OF CABLEPARKS IN THE WORLD

Read the BRUNO RIXEN LEGACY article

Find all wake spots in the world on